BANGKOK — As Thailand‘s tourist economy suffers a near-total shutdown from travel restrictions due to the new coronavirus, employees in the industry have been forced to improvise to make ends meet.

Air purser Kosit Rattanasopon, 37, has traded in his cabin crew uniform for a delivery driver’s jacket, stylishly ferrying food around Bangkok on his Ducati motorbike since the Thai airline he works for grounded all flights.

Kosit makes about 1,000 baht ($31.13; $1 = 32.1200 baht) per day, just enough to support his father and sister, who also cook boxed meals to sell online.

“I know things will not be the same again for at least another year, so I will have to keep doing this,” he said.

Tourism accounted for 11% of Thailand‘s GDP last year, and border closures and travel restrictions to prevent its spread are expected to decimate the industry for months to come.

Those who have new jobs are among the fortunate. Some 4 million Thais work in the tourism sector, and most face a year or more of lost income until a vaccine or new coronavirus treatment allows travel to return to previous levels.

Another grounded airline worker, stewardess Thawanan Thawornphatworakul, has transformed her living room into a hair salon.

She averages two to three clients per day and charges 150 baht ($4.67) per cut. Thawanan, 36, said her income is nowhere near her airline salary, but it helps.

“The income here helps with some expenses and pays the bills,” she said.

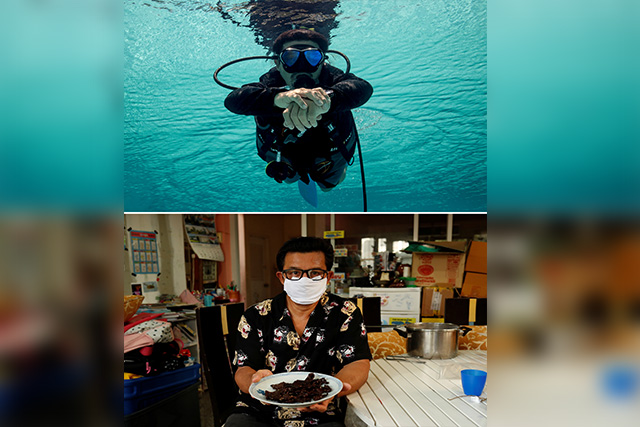

Scuba diving instructor Sermsak Posayajinda, 47, has also found a new income source, making jars of chili paste from his mother’s recipes and selling them online.

A combination picture shows scuba diving instructor Sermsak Posayajinda diving in a swimming pool (top) and posing with a plate of fried dry beef which he cooks to sell online (bottom) as Thais adapt to the new economic reality during the coronavirus disease (COVID-19) outbreak in Bangkok, Thailand May 5, 2020. Pictures taken May 5, 2020. (Reuters/Jorge Silva)

“At first it was only a hobby during COVID-19 period, but the results have been very good, so this will become a business for us in the long term,” Sermsak said.

Closure of hotels and exhibition centers also disrupted the business of Asaree Jarugosol, 36, who rents out chairs and builds stages for hotels and caterers around Bangkok.

Asaree decided to retain all her staff by transforming her warehouse into a factory that makes 2,500 reusable face masks per day, first for local hospitals and now for exporting overseas as worldwide demand surges.

“At first we only have one sewing machine operated by one staff … but now we have some 40 people working a proper production line,” Asaree said.

“We will continue to produce face masks even when our old business returns.” —Reporting by Jiraporn Kuhakan and Jorge Silva; Additional report by Athit Perawongmetha. Writing by Panu Wongcha-um. Editing by Kay Johnson and Ed Osmond